Fowler A7 Road Loco

I have started building a 2" Fowler Road Loco. Initially, I bought some castings and parts from MJ Engineering, UK. I have previously built stationary model Steam Engines, Stirling Engines, a 16mm Steam Loco (Brazil) and a 2HP Reversing Column Marine Engine using Hasbrouck Plans (#10). This 2" Fowler Road Loco is my first Traction Engine. For this 2" Fowler Road Loco, I intend to build all the other parts by myself as far as possible .

I began my Work on June 2009.

Current Progress Of the Fowler

Castings and Parts

I completed fabricating the Front wheels by the mid week of July (2009).

Front Wheels

The Hind wheel hubs were setup on the milling machine to mill the groves for spokes, They were completed by the third week of July (2009).

The hind wheel hubs were completed by the end of July (2009).

By the dawn of August (2009), Hind wheels were completed.

By the end of September (2009), Fron axle Fork, Winding drum, Driving Plate Outer along with the Driving Plate were completed.

The Crankshaft along with the other shafts, completed on September (2009).

The inner crankshaft ends were machined between 0.02 to 0.03 mm more than the ID of the webs, and then press fitted together.

After 5 months of work, I felt that my desire to build a fowler is more challenging task than my previous engineering projects. However, I feel content with the progress I made in 5 months time.

Photos of Chimney, Smoke box, Front Axel and the Forecarriage.

By the Third week of November, On the day The Leonids Meteor shower reached its peak, The fowler was once again prepared for a round of photos. Allthough i missed the Meteor show and a fine photoshoot that night, I achieved a much more complicated and a challenging goal.. After 2 months of Hard work, The fowler was finally on its Wheels.

Fowler Assembled

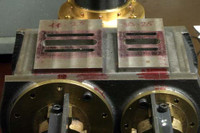

Both the Cylinder Bores were plugged with two aluminum plugs,with centers marked and taking those marks as reference, it was mounted in the milling machine to mill the saddle. The milling machine is a German made Steinel FVK3 which was with me for the past 20 years. After the saddle was made, it was mounted in the faceplate to bore the high pressure and low pressure cylinders. Finally it was moved on to the milling machine again to mill the ports.

The crossheads and the connecting rods are being completed at the moment, once they are completed, More photos will be updated.

I am really happy that I am able to start posting about the progress of my Fowler A7. The work had to be stopped during the past two years due to unavoidable circumstances. The work recommenced from last January. I posted some photos of the cylider block, in my prevoius posting of the 15th. April 2010. At present almost all the machining of the cylinder block is completed.

Please find below some photos showing the present situation of the cylinder block.

I came across a nice article about drilling steam passages in the "homemodelenginemachinist" forum. The drilling was done according to the description, and with the help of the wonderfull fixture graphically illustrated.

More Photos !!!

During the past few months I did not have much time to take pictures of my Fowler.

These photos were taken a few minuites ago.

In the early 1950s as a child I can faintly remeber one or two traction engines on the road, doing road maitenance work. I am not sure whether they were runing on steam either. But I can remember very clearly the revolving Governor.

So after assebmling the parts together I applied some compressed air ionto the boiler and got my Fowler in action for the first time. I was very much facinated to see the Governor revolving again as I saw it in my child hood. As far as I know there are no Steam powered Traction engines (in fact no traction engines of any kind) which are in working order in Sri Lanka at present.

The engine runs at a minimum air pressure of about 6 psi. I will post a link of a video clip of my fowler running on air soon.

Here is video of my Fowler Traction Engine running on air!!